济南鑫鲁泉盛机械设备有限公司

济南鑫鲁泉盛机械设备有限公司

服务热线:15662735099

联系地址:山东章丘枣园经济开发区

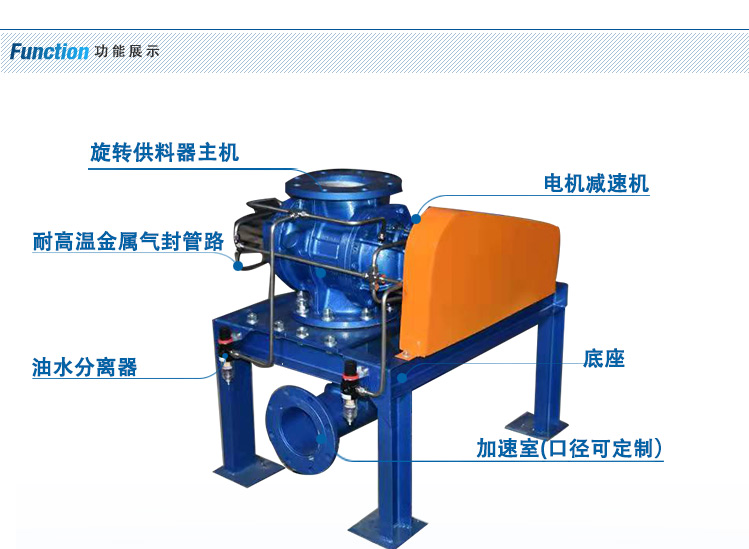

气力输送设备中的旋转供料器叶片具有优良的耐磨性能,锁气效果突出、卸料过程彻底干净、整体结构紧凑且严实。它采用弹性转子设计,使得密封性能更为优异,能够稳定保证物料的均匀喂送。其组成部分包括阀体、传动轴、叶片以及减速器等关键部件。

The rotating feeder blades in pneumatic conveying equipment have excellent wear resistance, outstanding air locking effect, thoroughly clean unloading process, compact and tight overall structure. It adopts an elastic rotor design, which makes the sealing performance more excellent and can stably ensure the uniform feeding of materials. Its components include key parts such as valve body, transmission shaft, blades, and reducer.

减速电机作为动力源,带动传动轴与叶轮进行转动,进而实现卸灰的操作目的。该设备运用了行星转动的原理,让输入轴与输出轴处于同一条轴线上,并且具备与电机直接连接成一体的独特特性,正因如此,它的结构十分紧凑、造型新颖且美观大方,同时还具有体积小、重量轻的优势。

As a power source, the deceleration motor drives the transmission shaft and impeller to rotate, thereby achieving the purpose of ash unloading operation. This device utilizes the principle of planetary rotation, allowing the input shaft and output shaft to be on the same axis, and has the unique feature of being directly connected to the motor as a whole. Therefore, its structure is very compact, the shape is novel and beautiful, and it also has the advantages of small size and light weight.

旋转供料器的密封性能表现出色,给料过程均匀且稳定,卸料运行状态平稳,工作时产生的噪音小,出现故障的概率低,使用寿命较长,耐磨程度也很高。其中的轴承、齿箱等部件远离阀体,能够有效避免受到高温粉尘的不良影响,前后端盖的密封效果良好,可以防止粉尘向外泄漏,这一设计有助于延长运动部件和润滑系统的使用年限。

The sealing performance of the rotary feeder is excellent, the feeding process is uniform and stable, the unloading operation is smooth, the noise generated during operation is small, the probability of failure is low, the service life is long, and the wear resistance is also high. The bearings, gearboxes, and other components are located away from the valve body, effectively avoiding the adverse effects of high-temperature dust. The sealing effect of the front and rear end caps is good, which can prevent dust leakage outward. This design helps to extend the service life of moving parts and lubrication systems.

它的输送能力较强,耐受冲击的惯性力小,非常适合用于需要频繁起动以及正反转操作的场景。在吸收球的气力输送过程中,旋转供料器是一个至关重要的设备,其主要的功能是对堆芯落球孔道中的吸收球颗粒进行初始的流态化处理,从而形成气固两相流。由于旋转供料器被设置在反应堆压力容器内部,进行维修操作存在诸多不便,所以它对于吸收球初始流态化的可靠性和稳定性有着极高的要求。旋转供料器的结构是影响其工作性能的一个重要因素,在 10MW 高温气冷实验堆的吸收球停堆系统中,所使用的是诱导式旋转供料器,其气力输送方式为吸送式,并且搭建了以常温常压空气作为气源的负压吸收方式。相关的试验结果表明,流化管式旋转供料器在吸收球的流态化顺畅性以及重启可靠性方面,都要优于另外两种旋转供料器,不过,关于流化管式旋转供料器的吸收球输送速率以及压降随着空气流速变化的规律,目前尚未有相关的报道。

It has strong conveying capacity and low inertia force to withstand impact, making it very suitable for scenarios that require frequent starting and forward/reverse operations. In the pneumatic conveying process of absorbing balls, the rotary feeder is a crucial equipment, whose main function is to perform initial fluidization treatment on the absorbing ball particles in the core falling ball hole, thereby forming gas-solid two-phase flow. Due to the fact that the rotary feeder is located inside the reactor pressure vessel, there are many inconveniences in maintenance operations, so it has extremely high requirements for the reliability and stability of the initial fluidization of the absorption ball. The structure of the rotary feeder is an important factor affecting its performance. In the absorption ball shutdown system of the 10MW high-temperature gas cooled experimental reactor, an induced rotary feeder is used, and its pneumatic conveying method is suction type. A negative pressure absorption method using normal temperature and pressure air as the gas source is also established. The relevant experimental results show that the fluidized tube rotary feeder is superior to the other two types of rotary feeders in terms of the smoothness of fluidization and restart reliability of the absorption balls. However, there are currently no relevant reports on the law of the absorption ball conveying rate and pressure drop of the fluidized tube rotary feeder changing with the air flow velocity.

本文由旋转供料器友情奉献.更多有关的知识请点击:http://www.xinluquansheng.com/我们将会对您提出的疑问进行详细的解答,欢迎您登录网站留言.

This article is dedicated to friendship For more information, please click: We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

2024 济南鑫鲁泉盛机械设备有限公司 备案号:鲁ICP备18012408号-3 鲁公网安备37018102000806号